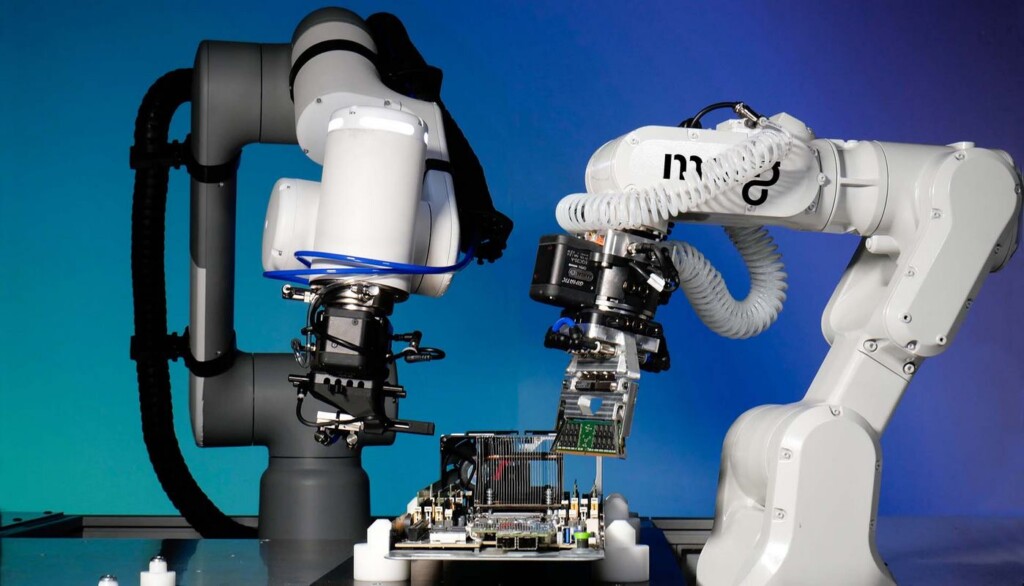

Credit – Molg, released to the media

Credit – Molg, released to the mediaA former tech hardware entrepreneur has refocused his talents on tackling the problem of electronic device waste.

His startup manufactures and programs precision robots to delicately take apart products and separate still-useable components for reuse, not recycling.

Rob Lawson-Shanks is his name, and having just been bankrolled by some of the biggest names in stakeholder venture capitalism, he’s not only helping recycling facilities disassemble electronics that would previously be scrapped, but also working with companies like Dell to design new devices that are easier for his robots to unmake.

“I started to realize I was contributing to this massive, 60-million-ton problem of e-waste because of how we were designing, manufacturing, and ultimately not recovering

The GNN Paperback Book: “And Now, The Good News”

$14.95 Original price was: $14.95.$13.99Current price is: $13.99. More Details

The Nutrition Company On a Mission to Help Others

$25-$88 $21.25– $74.80 More Details

Holistic Patches Relieve Anxiety – Without Drugs

$29.95 More Details

‘Within Good There is God’ Reminder Bracelet (with Canvas Pouch)

$29.99 $26 More Details

A Daily Dose of Positive Affirmations–Right on Your Toes

$14.99 $13.50 More Details

The Heartwarming Feel-Good Book We All Need

15.99 10.49 More Details

N95 Scarf and Mask Filter the Air Around You By 99%

$29-$69 More Details

Fresh Roasted Fire Dept. Coffee

$11.99 Original price was: $11.99.$10.80Current price is: $10.80. More DetailsHis company Molg makes and programs robots that use multiple arms and cameras with extraordinary delicacy to remove panels, unscrew fasteners, and extract chips all on their own.

“We use really high-precision, non-destructive [equipment], and really care about what we’re touching and then moving so that we can retest, re-qualify, and redeploy,” Lawson-Shanks says. “Ultimately, it’s to try and keep things at the highest value possible.”

The small systems—10 feet by 3 feet by 10 feet tall—are designed to fit inside existing e-waste processing facilities. They can take apart some devices in as fast as five minutes. At the moment, the machines are excellent at taking apart old servers to recover components to make new units for data centers.

GREEN CAPITALISM: Tuscany’s New Airport Terminal Will Have a Vineyard on the Roof, Obviously

The idea is that each time a Molg “microfactory,” as they’re called, disassembles something, the components inside are tracked and databased before being used in a mid-tier market item. When that item is broken down, the same components can be used to make a simpler electronic product, and all the way until its material structure breaks down and goes to be recycled.

Ideally, Lawson-Shanks said, devices in our society should be built with components that can be scavenged 4 to 5 times before needing to be recycled.

MORE STORIES LIKE THIS: LEGO Invests to Make Half the Plastic in Its Bricks from Renewable Materials by 2026

Partnering with companies like Dell, Molg has rolled out a whole new set of snaps, press-fits, latches, and other modular connections that can help bind laptops and other devices together but that can be easily disengaged, removed, or unsnapped by its microfactories.

SHARE This Impressive Invention And Its Power To Change Manufacturing…

Source link